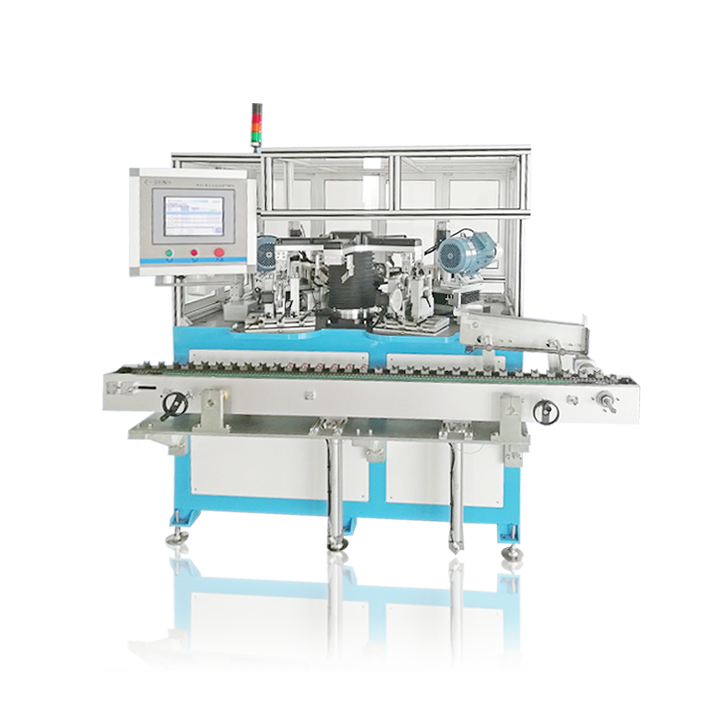

Foshan Huake Zhichuang Intelligent Equipment Co., Ltd. released the balancing machine HK-BQ5T, which is suitable for all kinds of micro and small winding armature rotor dynamic balance correction.

Product features

1. Super wide application range

The detection system of BQ5T is composed of stepping assembly, high-precision displacement sensor, signal processing board and algorithm interface.

The detection part adopts soft support, which can achieve the purpose of high-precision detection of various weight rotors by switching different reeds.

The pre-design of fine-tuning device also makes the operation more convenient and easy.

2. Rotary manipulator

Adopting rotary conveyance mechanism, stable operation and simple maintenance under high speed. Servo motor drive, can run at any Angle, at any speed, can run continuously 360 degrees in the same direction, without reciprocating motion, reduce movement action, improve the life of parts.

Air-electric integrated slip ring, standard air claw installation, easy to purchase accessories, easy to replace.

Large stroke clamping workpiece, wider scope of application!

Each action has position detection, clamping device has double detection function of air pressure detection, as far as possible to reduce the occurrence of false action.

3. Feeding and storage function

There is a feeding chain, which can be manually loaded and unloaded, or directly connected to the upper and lower processes. PLC has redundant ports for connecting.

4. Light cutting applications for heavy cutting mechanisms

Guide post guide sleeve mechanism because it belongs to the sliding surface contact bearing, with high precision, high rigidity and other characteristics, so it is used in the mold industry, and the machine cutting feed mechanism also adopts the 4 guide pillar structure, MISUMI guide sleeve component, making the rigidity of the whole cutting system greatly increased, The increased rigidity further reduces the error between the actual cutting amount and the theoretical cutting amount, and improves the pass rate.

5. Automatic discharging sorting

The discharging station is provided with an unqualified product storage bin for storing the unqualified products automatically removed. (The main source of nonconforming products is unbalance out of tolerance and other testing items such as minor failure of external equipment marked products.)

6. Formula function

The device has built-in formula storage function, which can conveniently store the production process data of different workpieces. When the same workpieces are produced next time, the parameters can be directly called out to avoid repeated adjustment and waste of time.

Formula data support replication function, can reduce the parameter setting of similar workpiece, formula name support Chinese and English, case and number input.

7. Digital touch control interface

Select advanced touch control screen, with well-designed operation interface, friendly operation guidance process, with internal intelligent algorithm structure, make the whole equipment to the most concise operation mode and the most intelligent operation logic form to the user.

8. High quality standard parts

The whole machine from the project design stage will be quality design as the basic design goal, so no matter from the sensor, cylinder, or to PLC, stepper, servo and other parts, all choose the industry quality benchmark suppliers to provide parts. The following is part of the brand introduction of the device.

| Pneumatic components | AirTAC |

| Feeding cylinder | SMC |

| Positioning sensor | MEIJI DENKI |

| PLC | KEYENCE |

| Touch screen | KUNLUNTONGTAI |

| Linear bearing | HIWIN |

| Ball screw | TBI |

| Guide post assembly | MISUMI |

| Servo, stepping | MOONS |

| Cutting motor | ABB |

| Electrical auxiliary parts | SCHNEIDER |

Welcome to visit our inspection guidance!