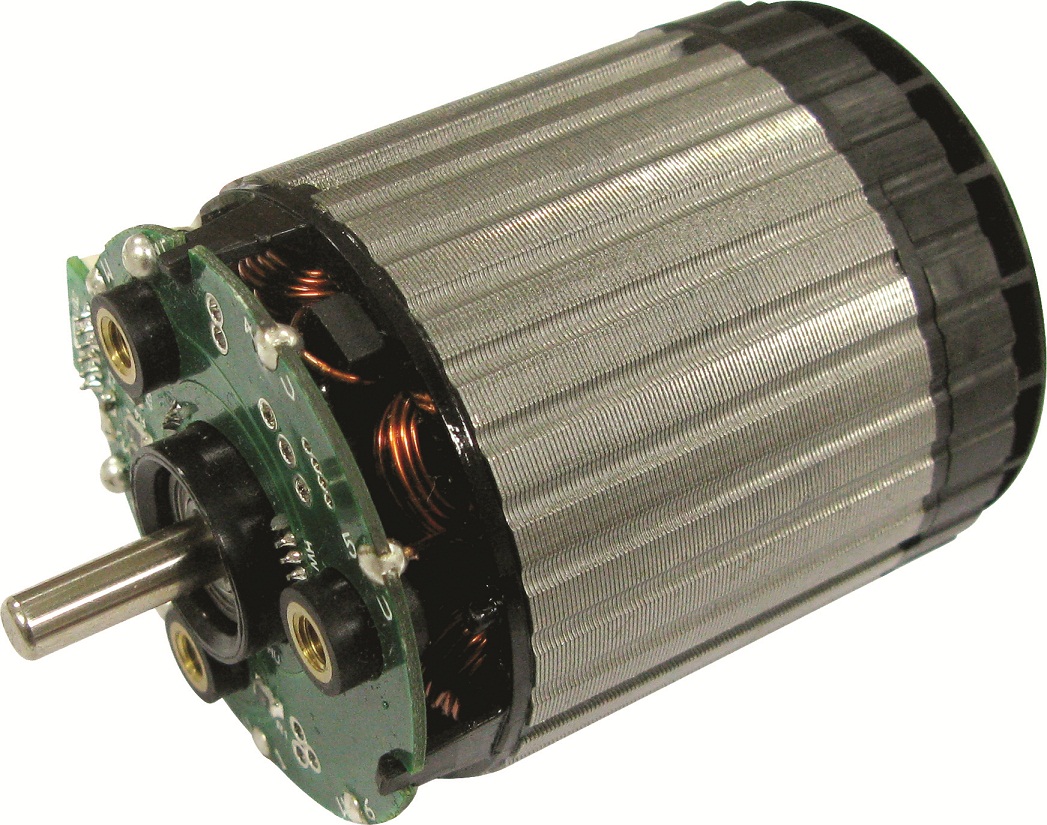

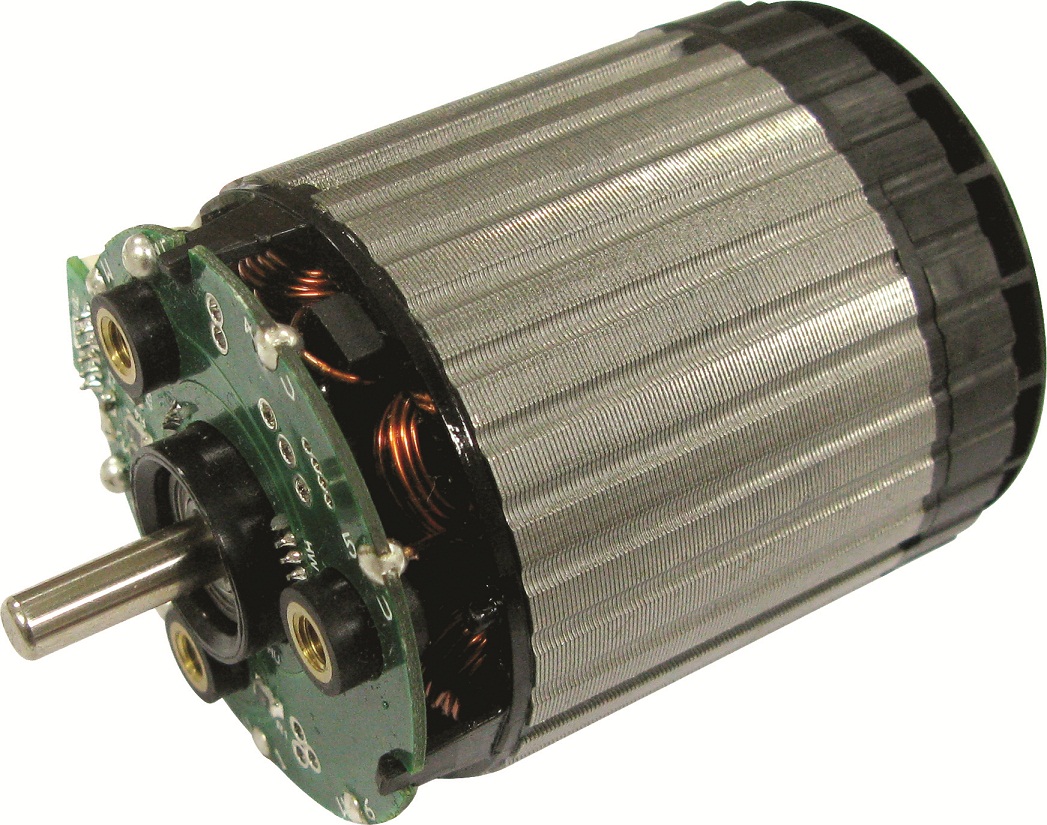

Brushless motor is mainly composed of motor and driver. Brushless motor belongs to Mechatronics equipment. Brushless motor has a short development time in China. With the rapid development of science and technology in China, brushless motor has been applied in many fields, such as household appliances, toys, models, electric vehicles and so on. More use will also lead to a variety of topics, one of the most critical balance problems, now let's take a look at how brushless motors should choose dynamic balancer.

The centrifugal force of any rotor rotating around its axis due to uneven mass distribution relative to its axis will cause vibration on the bearings of the rotor caused by this unbalanced centrifugal force, resulting in noise and accelerating bearing wear and tear which will seriously affect the performance and life of the product. In order to control vibration, noise and service life of brushless motor, the rotor dynamic balance accuracy of brushless motor must be achieved to a higher level. Selecting the automatic balancing machine for brushless motor developed by Shenman can effectively solve the dynamic balance problem of rotor and improve production efficiency.

When choosing the dynamic balancing machine, we should not only entangle the type of dynamic balancing machine, nor blindly listen to others or online comments to select the type of dynamic balancing machine. We should explore everything by ourselves, and the best basis for judging the type is the answer we get.

Brushless Motors should first consider whether to do a good job with vertical or horizontal dynamic balancing machines. In fact, there is no exact answer or statement to this question. Because as long as the type of dynamic balancer can achieve high accuracy and stable detection, the type of dynamic balancer is acceptable. The purpose of the test is to see if the final result can meet the user's requirements.

In addition, the accuracy and stability of dynamic balancing machine detection are also the criteria of judgment, as long as the vertical or horizontal dynamic balancing machine is selected, whichever type can meet this requirement. Some balancers have made the correcting device part of the balancer. Gravity balancer and centrifugal force balancer are two typical types of balancer. Gravity balancer is generally called static balancer.

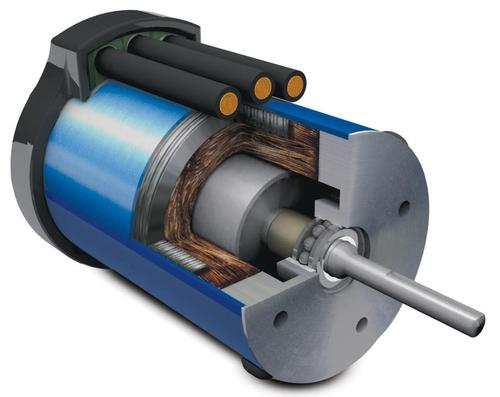

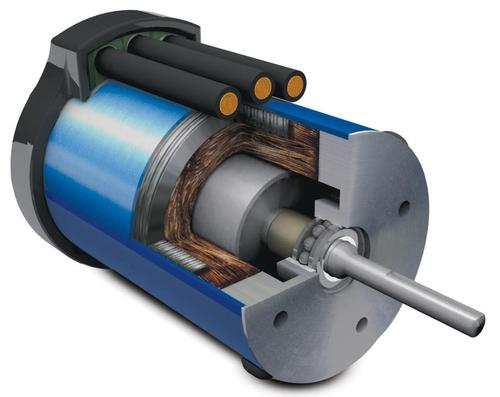

Motor rotor dynamic balancer

Therefore, the balancer is indispensable to reduce vibration, improve performance and improve quality. Usually, rotor balance includes two steps: measurement and correction of unbalance. Balancer is mainly used to measure unbalance, while adjustment of unbalance is usually done by hand or by other auxiliary equipment such as drilling machine, milling machine and spot welder.

In the manufacturing process, rotating parts such as motor rotor, machine tool spindle, internal combustion engine crankshaft and turbine rotor, gyroscope rotor and clock pendulum wheel need to be balanced to run smoothly and normally. Correction of the rotor imbalance based on the measured data of the balancer can improve the mass distribution of the rotor relative to the axis and reduce the vibration force generated by the rotor rotation or acting on the bearing to the allowable range.

The centrifugal force of any rotor rotating around its axis due to uneven mass distribution relative to its axis will cause vibration on the bearings of the rotor caused by this unbalanced centrifugal force, resulting in noise and accelerating bearing wear and tear which will seriously affect the performance and life of the product. In order to control vibration, noise and service life of brushless motor, the rotor dynamic balance accuracy of brushless motor must be achieved to a higher level. Selecting the automatic balancing machine for brushless motor developed by Shenman can effectively solve the dynamic balance problem of rotor and improve production efficiency.

When choosing the dynamic balancing machine, we should not only entangle the type of dynamic balancing machine, nor blindly listen to others or online comments to select the type of dynamic balancing machine. We should explore everything by ourselves, and the best basis for judging the type is the answer we get.

Brushless Motors should first consider whether to do a good job with vertical or horizontal dynamic balancing machines. In fact, there is no exact answer or statement to this question. Because as long as the type of dynamic balancer can achieve high accuracy and stable detection, the type of dynamic balancer is acceptable. The purpose of the test is to see if the final result can meet the user's requirements.

In addition, the accuracy and stability of dynamic balancing machine detection are also the criteria of judgment, as long as the vertical or horizontal dynamic balancing machine is selected, whichever type can meet this requirement. Some balancers have made the correcting device part of the balancer. Gravity balancer and centrifugal force balancer are two typical types of balancer. Gravity balancer is generally called static balancer.

Motor rotor dynamic balancer

Therefore, the balancer is indispensable to reduce vibration, improve performance and improve quality. Usually, rotor balance includes two steps: measurement and correction of unbalance. Balancer is mainly used to measure unbalance, while adjustment of unbalance is usually done by hand or by other auxiliary equipment such as drilling machine, milling machine and spot welder.

In the manufacturing process, rotating parts such as motor rotor, machine tool spindle, internal combustion engine crankshaft and turbine rotor, gyroscope rotor and clock pendulum wheel need to be balanced to run smoothly and normally. Correction of the rotor imbalance based on the measured data of the balancer can improve the mass distribution of the rotor relative to the axis and reduce the vibration force generated by the rotor rotation or acting on the bearing to the allowable range.

351 browse