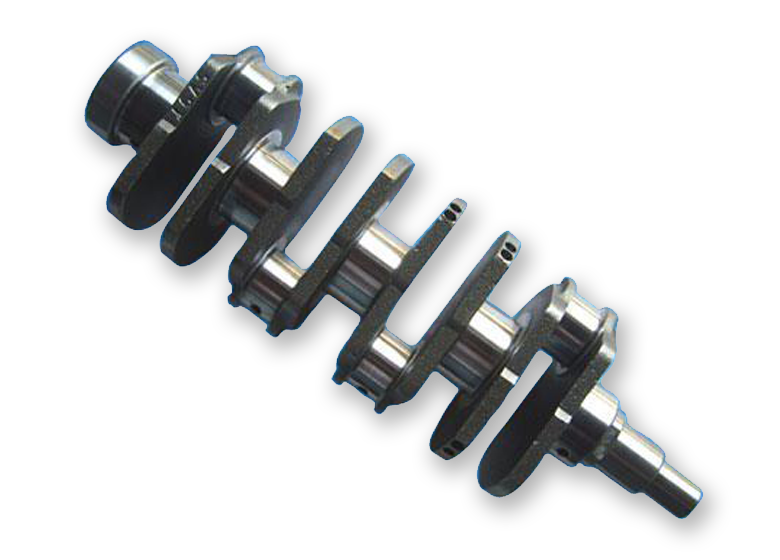

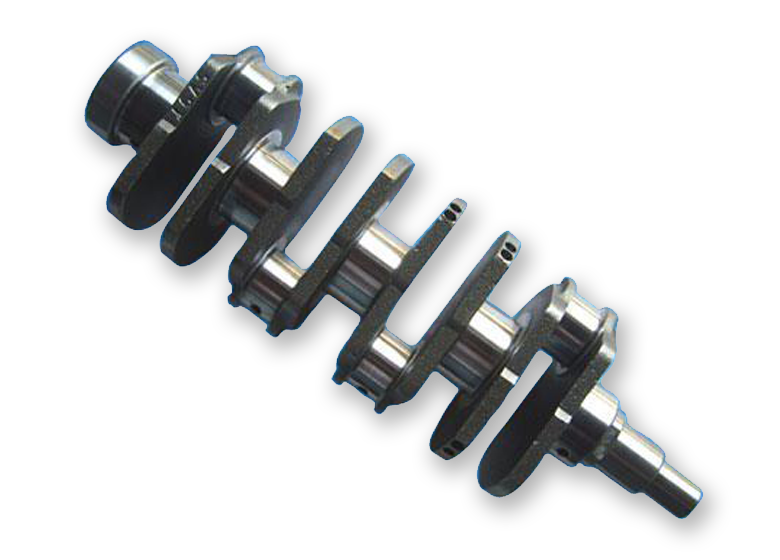

Crankshaft dynamic balance processing is listed as the key processing procedure in the 36 processing procedures of automobile engine crankshaft. The poor precision of dynamic balance processing will cause excessive vibration of the vehicle while driving, which will affect the driving smoothness and even cause crankshaft breakage and bring about safety accidents. Dynamic balance testing technology and signal processing technology are developing rapidly. Although a series of tests, adjustments and comparisons have been made in machining, the dynamic balance stability of crankshaft is not good enough, so it is necessary to find out the cause of measurement stability and find new solutions.

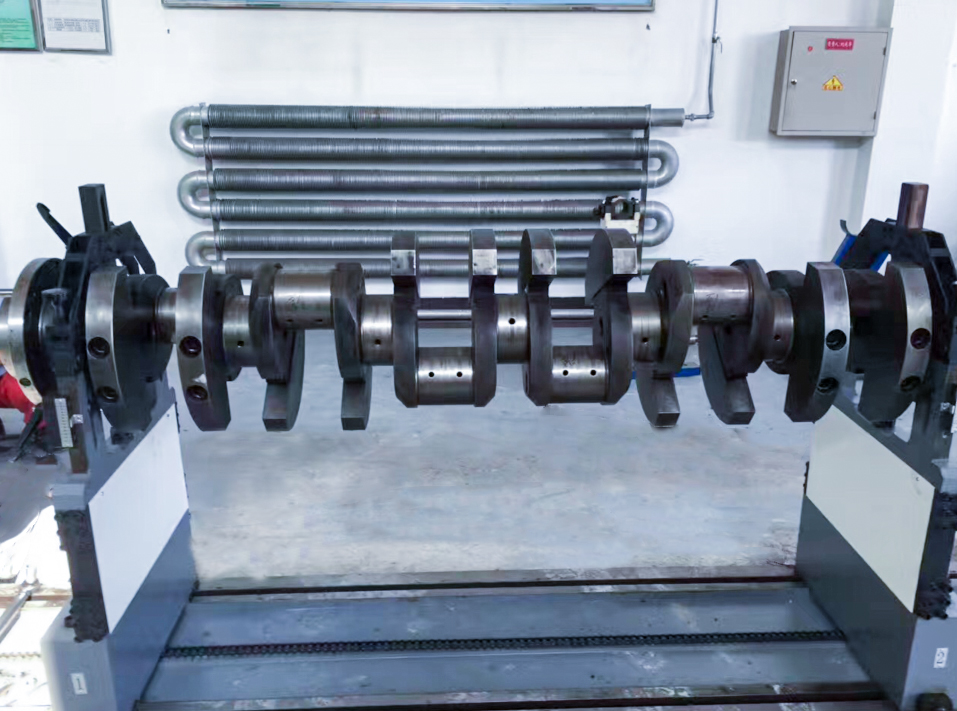

How to select the dynamic balancing machine when the crankshaft is checking the dynamic balance? Different working principles of soft-supported and hard-supported dynamic balancing machines inevitably result in different structures and operating methods, which bring about their respective advantages and disadvantages, which need careful analysis when selecting. Some balancing tasks must use soft support, some must use hard support, some are better, and some have more obvious advantages of hard support.

1. For large-scale production of light and small crankshafts, the specifications of balancing crankshaft are generally limited and it is basically known when purchasing the balancing machine. Soft-supported balancing machine should be selected at this time. Its advantage of high sensitivity is brought into play, and the influence of parasitic quality is controlled by the manufacturer within the range of not affecting accuracy. Limited sets of calibration data can be stored in the measuring instrument and can be used by the operator as a permanent calibration.

2. For mass production of crankshaft with certain weight, its characteristics are that the rotor specifications are small and basically known, but the impact resistance is required to be higher. At this time, the hard-supported balancing machine should be used, but the work is beyond the permanently calibrated range and close to the resonance zone (also called semi-hard balancing machine). At this time, high sensitivity can be obtained, and the structure is robust and reliable.

3. Most of them belong to single-piece or small or medium-sized batch crankshaft production or maintenance. The rotor specifications required for balancing are numerous and unpredictable. At this time, a universal crankshaft dynamic balancing machine is required. The hard-supported balancing machine has its unique advantages at this time. Its advantages of permanent calibration, large initial imbalance and high reliability are brought into play.

Huake Zhichuang is an advocate of learning the concepts of German and Japanese mechanical design and production. He now has a professional R&D team, which can improve and improve the equipment technology according to the existing dynamic balancing machines of users, and can also provide non-standard balancing machines tailored to the special workpiece requirements of users.

Huakezhi Creative Dynamic Balancer uses high-quality electronic original parts and imported original parts as its core components, which better guarantees the stability of dynamic balancing equipment and the service life of equipment, and better guarantees the high-quality and standard requirements of products. Localized production, better reduce the cost of transportation and maintenance of imported equipment, but also enable users to purchase the most practical products with the most economic efforts, thus making our products more competitive in the market. If you have friends who need dynamic balancing machine, please feel free to contact us for technical customer service.

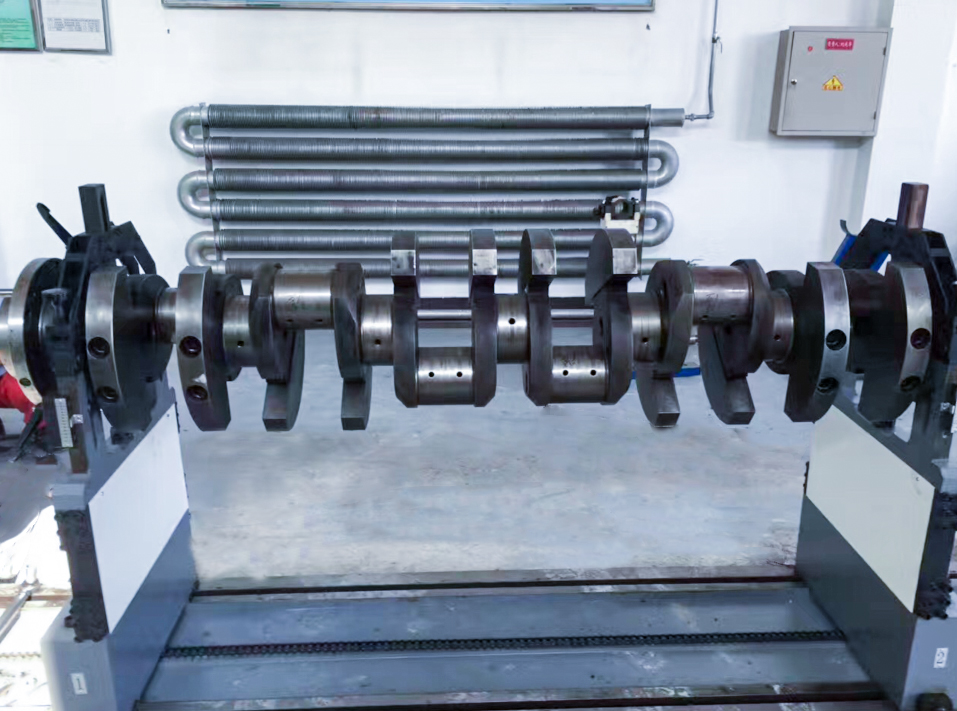

How to select the dynamic balancing machine when the crankshaft is checking the dynamic balance? Different working principles of soft-supported and hard-supported dynamic balancing machines inevitably result in different structures and operating methods, which bring about their respective advantages and disadvantages, which need careful analysis when selecting. Some balancing tasks must use soft support, some must use hard support, some are better, and some have more obvious advantages of hard support.

1. For large-scale production of light and small crankshafts, the specifications of balancing crankshaft are generally limited and it is basically known when purchasing the balancing machine. Soft-supported balancing machine should be selected at this time. Its advantage of high sensitivity is brought into play, and the influence of parasitic quality is controlled by the manufacturer within the range of not affecting accuracy. Limited sets of calibration data can be stored in the measuring instrument and can be used by the operator as a permanent calibration.

2. For mass production of crankshaft with certain weight, its characteristics are that the rotor specifications are small and basically known, but the impact resistance is required to be higher. At this time, the hard-supported balancing machine should be used, but the work is beyond the permanently calibrated range and close to the resonance zone (also called semi-hard balancing machine). At this time, high sensitivity can be obtained, and the structure is robust and reliable.

3. Most of them belong to single-piece or small or medium-sized batch crankshaft production or maintenance. The rotor specifications required for balancing are numerous and unpredictable. At this time, a universal crankshaft dynamic balancing machine is required. The hard-supported balancing machine has its unique advantages at this time. Its advantages of permanent calibration, large initial imbalance and high reliability are brought into play.

Huake Zhichuang is an advocate of learning the concepts of German and Japanese mechanical design and production. He now has a professional R&D team, which can improve and improve the equipment technology according to the existing dynamic balancing machines of users, and can also provide non-standard balancing machines tailored to the special workpiece requirements of users.

Huakezhi Creative Dynamic Balancer uses high-quality electronic original parts and imported original parts as its core components, which better guarantees the stability of dynamic balancing equipment and the service life of equipment, and better guarantees the high-quality and standard requirements of products. Localized production, better reduce the cost of transportation and maintenance of imported equipment, but also enable users to purchase the most practical products with the most economic efforts, thus making our products more competitive in the market. If you have friends who need dynamic balancing machine, please feel free to contact us for technical customer service.

313 browse