The specific method of crankshaft dynamic balance correction depends first on the processing quantity, and the entire process is quite complex. Huake Zhichuang Dynamic Balance Machine Factory will provide a detailed analysis for everyone below. The crankshaft rotates at high speed during operation, and if the balance is not good, it will generate momentum peaks, which can seriously break. Usually, through dynamic balancing machine testing, some materials are reduced in the non stressed parts of the crankshaft. All high-speed rotating parts need to undergo balance testing, such as flywheels, transmission shafts, high-speed spindles, etc.

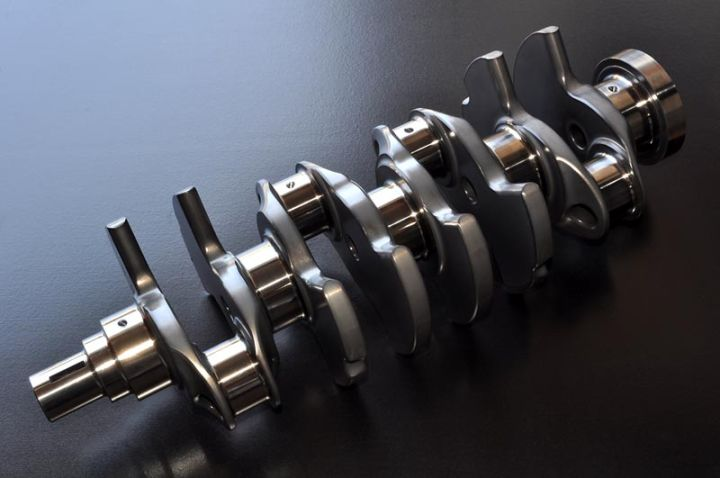

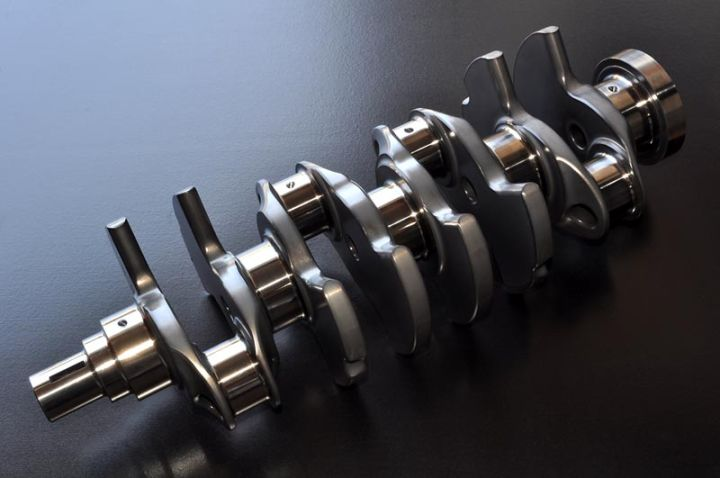

The crankshaft is the main rotating component of the engine. After installing the connecting rod, it can undertake the up and down (reciprocating) motion of the connecting rod and become a cyclic (rotating) motion. It is an important component of the engine. Rotation produces vibration, so dynamic balancing is necessary. Special crankshaft dynamic balancing machine series view click: Ring belt balancing machine, universal joint balancing machine

1、 Manufacturing blanks

1. If it is a single piece, it may be produced in small batches, sometimes using bar materials for direct processing. Simply put, it means hard cutting a casting rod into a crankshaft, which looks like a waste of material. In fact, it reduces the difficulty of casting and can save costs, but the requirements for processing equipment are relatively high; Perhaps free forging can be used to cast a bar into a shape that resembles a crankshaft, but casting requires a sufficiently large forging machine or a press machine

2. If processed in batches, usually die forging is used to directly cast the rod material, resulting in the appearance of the crankshaft. This method saves effort, labor, and materials, but making a set of molds is very expensive.

2、 Rough machining

1. Generally speaking, small factories or enterprises with small production scale can choose CNC lathes, crankshaft lathes, or simply use general lathes. The difficulty in machining the crankshaft lies in the machining of the "crankshaft", which is the connecting rod neck part, which requires the crankshaft to be clamped in a biased manner. Adjust the center of the "crank" section to be machined together with the spindle center of the lathe, and then process the "crank" one by one. For each machining, the crankshaft needs to be reinstalled, which is time-consuming and laborious. As for the main journal of the crankshaft, it is easy to directly turn it.

2. Professional processing factories generally choose CNC crankshaft milling machines. There are two types of crankshaft milling: internal milling and external milling. Internal milling has high accuracy and speed, but the price is more expensive, and can only process circular surfaces; External milling has low accuracy and slow speed, but it is cheaper than internal milling and can process flat surfaces. At the same time, when the machine tool scale is the same, external milling can process larger scales than internal milling. The crankshaft milling power is very high. Generally, the milling cutter rotates around the crankshaft for one cycle (internal milling, the crankshaft is within the cutter head), or perhaps the crankshaft rotates for one cycle (external milling), and the machining of a crankshaft as wide as the cutter head is completed. A crankshaft milling machine can easily top several CNC lathes, and top a dozen ordinary lathes.

3、 After rough machining of the heat treated crankshaft, the hardness is not acceptable. Quenching/nitriding is necessary to improve the hardness, and then tempering treatment is required to avoid cracking of the crankshaft.

4、 Fine machining heat treatment can cause slight deformation of the crankshaft, and in addition, the accuracy of the crankshaft itself does not meet the requirements, which requires the use of a grinding machine. Small batches can be used with general grinding machines, with very low power, especially when processing "cranks", which are the same as lathes and require one by one processing. Of course, there are also relatively advanced crankshaft grinders, especially CNC follow-up connecting rod neck grinders, which are also very beautiful in price... small and medium-sized ones worth 20 to 30 million yuan, and large ones worth 40 to 50 million yuan, without any caps (these are all considered half specialized machines and are all customized)

5、 In fact, the machining of the crankshaft itself is almost done here, and then operations such as flaw detection, polishing, and dynamic balancing are carried out.

Operation of the crankshaft: In terms of material, non quenched and tempered steel, which is currently energy-saving, efficient, and environmentally friendly green steel, is a new type of steel. It was introduced in early 1970s and has been less than 40 years since then. It is the addition of vanadium, titanium, and niobium microalloying elements to the foundation of medium carbon manganese steel, causing its solid solubility to decrease with cooling during the heating process. The microalloying elements vanadium, titanium, and niobium precipitate ferrite and pearlite, which are in a coherent relationship with the parent phase, strengthening the steel. Non quenched and tempered steel can be used to make balance machine parts, shortening the production cycle and saving energy. Individual ones can reduce energy consumption and production costs by 25% to 38%.

Nowadays, there are more and more non quenched and tempered steel forgings used for hot forging in the market. Non quenched and tempered steel crankshafts, connecting rods, camshafts and other internal combustion engine components have gained great operating space in industries such as internal combustion engine crankshafts and automobiles.

The crankshaft, also known as the engine spindle, was produced through multi tool turning and manual grinding processes in the early stages of engine operation. It received some praise and operation in the short term, and entered the 21st century. Due to the continuous advancement of equipment quality and processing requirements, low machining accuracy, and poor flexibility, it is gradually exiting the historical stage after leading for nearly half a century. The advanced equipment of high-speed and efficient composite processing technology has gradually entered the scale of engines and automobile balance machine crankshafts, and has been operated to a considerable extent in processing and production, which is a necessary trend for the growth of modern technology.

The crankshaft is an important component in the engine, made of carbon structural steel or ductile iron. The main journal is installed on the cylinder block, and the connecting rod journal is connected to the large end hole of the connecting rod. The small end hole on the connecting rod is connected to the cylinder piston, forming a standardized crank slider mechanism. The lubrication of the bearing shells between the crankshaft and the rocker arm is individually pressure lubricated. The crankshaft core is connected to the bearing shells through a process oil passage, and the engine is lubricated and cooled by pressure oil supplied by the oil pump during operation. The working process of the engine is the combustion and explosion of the mixed compressed gas, which promotes the piston and transmits force to the crankshaft through the connecting rod. The crankshaft changes the linear motion to the transformed motion.

An unbalanced crankshaft generates pressure on its supporting structure and the rotor itself during its rotation, leading to vibration. Therefore, dynamic balancing of the crankshaft is very necessary.

The crankshaft is the main rotating component of the engine. After installing the connecting rod, it can undertake the up and down (reciprocating) motion of the connecting rod and become a cyclic (rotating) motion. It is an important component of the engine. Rotation produces vibration, so dynamic balancing is necessary. Special crankshaft dynamic balancing machine series view click: Ring belt balancing machine, universal joint balancing machine

1、 Manufacturing blanks

1. If it is a single piece, it may be produced in small batches, sometimes using bar materials for direct processing. Simply put, it means hard cutting a casting rod into a crankshaft, which looks like a waste of material. In fact, it reduces the difficulty of casting and can save costs, but the requirements for processing equipment are relatively high; Perhaps free forging can be used to cast a bar into a shape that resembles a crankshaft, but casting requires a sufficiently large forging machine or a press machine

2. If processed in batches, usually die forging is used to directly cast the rod material, resulting in the appearance of the crankshaft. This method saves effort, labor, and materials, but making a set of molds is very expensive.

2、 Rough machining

1. Generally speaking, small factories or enterprises with small production scale can choose CNC lathes, crankshaft lathes, or simply use general lathes. The difficulty in machining the crankshaft lies in the machining of the "crankshaft", which is the connecting rod neck part, which requires the crankshaft to be clamped in a biased manner. Adjust the center of the "crank" section to be machined together with the spindle center of the lathe, and then process the "crank" one by one. For each machining, the crankshaft needs to be reinstalled, which is time-consuming and laborious. As for the main journal of the crankshaft, it is easy to directly turn it.

2. Professional processing factories generally choose CNC crankshaft milling machines. There are two types of crankshaft milling: internal milling and external milling. Internal milling has high accuracy and speed, but the price is more expensive, and can only process circular surfaces; External milling has low accuracy and slow speed, but it is cheaper than internal milling and can process flat surfaces. At the same time, when the machine tool scale is the same, external milling can process larger scales than internal milling. The crankshaft milling power is very high. Generally, the milling cutter rotates around the crankshaft for one cycle (internal milling, the crankshaft is within the cutter head), or perhaps the crankshaft rotates for one cycle (external milling), and the machining of a crankshaft as wide as the cutter head is completed. A crankshaft milling machine can easily top several CNC lathes, and top a dozen ordinary lathes.

3、 After rough machining of the heat treated crankshaft, the hardness is not acceptable. Quenching/nitriding is necessary to improve the hardness, and then tempering treatment is required to avoid cracking of the crankshaft.

4、 Fine machining heat treatment can cause slight deformation of the crankshaft, and in addition, the accuracy of the crankshaft itself does not meet the requirements, which requires the use of a grinding machine. Small batches can be used with general grinding machines, with very low power, especially when processing "cranks", which are the same as lathes and require one by one processing. Of course, there are also relatively advanced crankshaft grinders, especially CNC follow-up connecting rod neck grinders, which are also very beautiful in price... small and medium-sized ones worth 20 to 30 million yuan, and large ones worth 40 to 50 million yuan, without any caps (these are all considered half specialized machines and are all customized)

5、 In fact, the machining of the crankshaft itself is almost done here, and then operations such as flaw detection, polishing, and dynamic balancing are carried out.

Operation of the crankshaft: In terms of material, non quenched and tempered steel, which is currently energy-saving, efficient, and environmentally friendly green steel, is a new type of steel. It was introduced in early 1970s and has been less than 40 years since then. It is the addition of vanadium, titanium, and niobium microalloying elements to the foundation of medium carbon manganese steel, causing its solid solubility to decrease with cooling during the heating process. The microalloying elements vanadium, titanium, and niobium precipitate ferrite and pearlite, which are in a coherent relationship with the parent phase, strengthening the steel. Non quenched and tempered steel can be used to make balance machine parts, shortening the production cycle and saving energy. Individual ones can reduce energy consumption and production costs by 25% to 38%.

Nowadays, there are more and more non quenched and tempered steel forgings used for hot forging in the market. Non quenched and tempered steel crankshafts, connecting rods, camshafts and other internal combustion engine components have gained great operating space in industries such as internal combustion engine crankshafts and automobiles.

The crankshaft, also known as the engine spindle, was produced through multi tool turning and manual grinding processes in the early stages of engine operation. It received some praise and operation in the short term, and entered the 21st century. Due to the continuous advancement of equipment quality and processing requirements, low machining accuracy, and poor flexibility, it is gradually exiting the historical stage after leading for nearly half a century. The advanced equipment of high-speed and efficient composite processing technology has gradually entered the scale of engines and automobile balance machine crankshafts, and has been operated to a considerable extent in processing and production, which is a necessary trend for the growth of modern technology.

The crankshaft is an important component in the engine, made of carbon structural steel or ductile iron. The main journal is installed on the cylinder block, and the connecting rod journal is connected to the large end hole of the connecting rod. The small end hole on the connecting rod is connected to the cylinder piston, forming a standardized crank slider mechanism. The lubrication of the bearing shells between the crankshaft and the rocker arm is individually pressure lubricated. The crankshaft core is connected to the bearing shells through a process oil passage, and the engine is lubricated and cooled by pressure oil supplied by the oil pump during operation. The working process of the engine is the combustion and explosion of the mixed compressed gas, which promotes the piston and transmits force to the crankshaft through the connecting rod. The crankshaft changes the linear motion to the transformed motion.

An unbalanced crankshaft generates pressure on its supporting structure and the rotor itself during its rotation, leading to vibration. Therefore, dynamic balancing of the crankshaft is very necessary.

240 browse