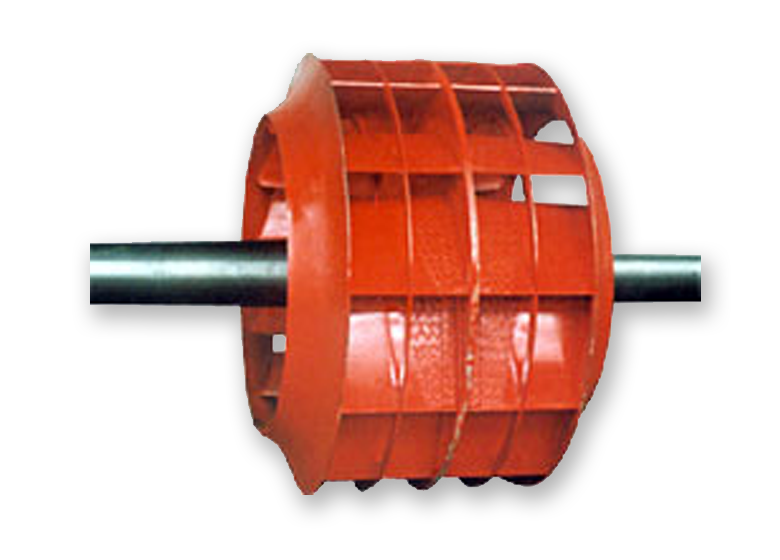

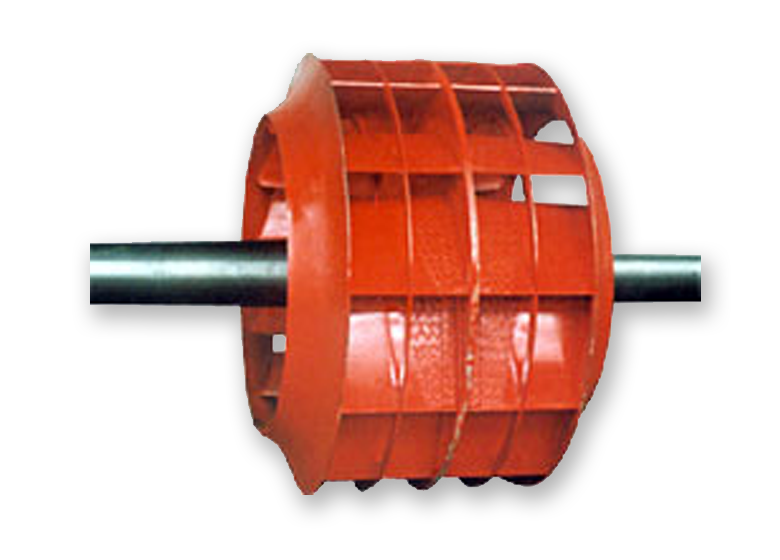

Today, Huake Zhichuang will provide a detailed explanation of the impeller wear of the impeller balancing machine and the treatment methods for the impeller scaling of the fan balancing machine. During the use of the impeller of the fan impeller balancing machine, if operated improperly, imbalance may occur. The causes of imbalance can be divided into: impeller wear, impeller balancing machine imbalance, impeller scaling, etc. The reasons for these situations are directly related to the dust removal device in front of the induced draft fan. The dry dust removal device can cause imbalance of the impeller, which can directly lead to impeller wear. The wet dust removal device can also affect the imbalance of the impeller, which can directly cause impeller scaling, among which impeller scaling is the most serious problem. After scaling on the impeller, it is necessary to handle it in a timely manner, otherwise it will have a significant impact on the impeller and even damage the impeller or equipment.

Impeller scaling high-pressure gas descaling: This method is composed of a nozzle, pipeline, and air source, and it has a very good descaling effect on the impeller. It can be descaled during the rotation gap of the impeller balance machine, and can be completed in just a few seconds. The operation is very simple, and can be descaled multiple times a day, which greatly reduces costs. It uses high-pressure resistant pipes, specialized nozzles, and high-pressure air sources.

Water spray descaling: This method is similar to a high-pressure gas descaling system. The water spraying system is installed on the casing of the impeller dynamic balancing machine, which is composed of three nozzles, pipelines, and drainage holes. The water source is tap water, and the pressure has certain requirements. This method has a good effect, but the disadvantage is that the time for each descaling is relatively long, and it requires multiple shutdowns per month to perform descaling, which will affect the normal use of the impeller dynamic balancing machine. Continuous airflow cleaning and scaling: Structurally speaking, the continuous blowing device does not require an external air source. It uses the exhaust pressure of the induced draft fan itself to direct a small amount of smoke (1% to 2% of the rated air volume) from the inside of the induced draft fan to a dedicated nozzle, which is located at the inlet of the impeller and shoots the smoke to the non working surface of the blade at a high speed. This blowing is continuous and begins with the opening of the induced draft fan, Not only does it blow off the dust that has just adhered to the blade, but it can also prevent dust deposition and thickening, without the need to shut down for descaling. The device has a simple structure, minimal modification to the induced draft fan, and good anti scaling effect, making it a promising new technology.

Regarding the issue of scaling on the impeller of the impeller balance machine mentioned above, we hope everyone can refer to it for scaling treatment, and the problems caused by the impeller should also be solved according to the actual situation. The scaling method of continuous airflow blowing is very suitable in many factories, because the scaling method of continuous airflow blowing can achieve continuous cleaning effect and solve the problem of dust accumulation caused by the impeller. Not only that, but also, This method does not require the equipment to be shut down during operation, which can effectively improve work efficiency and reduce consumption costs.

Impeller scaling high-pressure gas descaling: This method is composed of a nozzle, pipeline, and air source, and it has a very good descaling effect on the impeller. It can be descaled during the rotation gap of the impeller balance machine, and can be completed in just a few seconds. The operation is very simple, and can be descaled multiple times a day, which greatly reduces costs. It uses high-pressure resistant pipes, specialized nozzles, and high-pressure air sources.

Water spray descaling: This method is similar to a high-pressure gas descaling system. The water spraying system is installed on the casing of the impeller dynamic balancing machine, which is composed of three nozzles, pipelines, and drainage holes. The water source is tap water, and the pressure has certain requirements. This method has a good effect, but the disadvantage is that the time for each descaling is relatively long, and it requires multiple shutdowns per month to perform descaling, which will affect the normal use of the impeller dynamic balancing machine. Continuous airflow cleaning and scaling: Structurally speaking, the continuous blowing device does not require an external air source. It uses the exhaust pressure of the induced draft fan itself to direct a small amount of smoke (1% to 2% of the rated air volume) from the inside of the induced draft fan to a dedicated nozzle, which is located at the inlet of the impeller and shoots the smoke to the non working surface of the blade at a high speed. This blowing is continuous and begins with the opening of the induced draft fan, Not only does it blow off the dust that has just adhered to the blade, but it can also prevent dust deposition and thickening, without the need to shut down for descaling. The device has a simple structure, minimal modification to the induced draft fan, and good anti scaling effect, making it a promising new technology.

Regarding the issue of scaling on the impeller of the impeller balance machine mentioned above, we hope everyone can refer to it for scaling treatment, and the problems caused by the impeller should also be solved according to the actual situation. The scaling method of continuous airflow blowing is very suitable in many factories, because the scaling method of continuous airflow blowing can achieve continuous cleaning effect and solve the problem of dust accumulation caused by the impeller. Not only that, but also, This method does not require the equipment to be shut down during operation, which can effectively improve work efficiency and reduce consumption costs.

252 browse