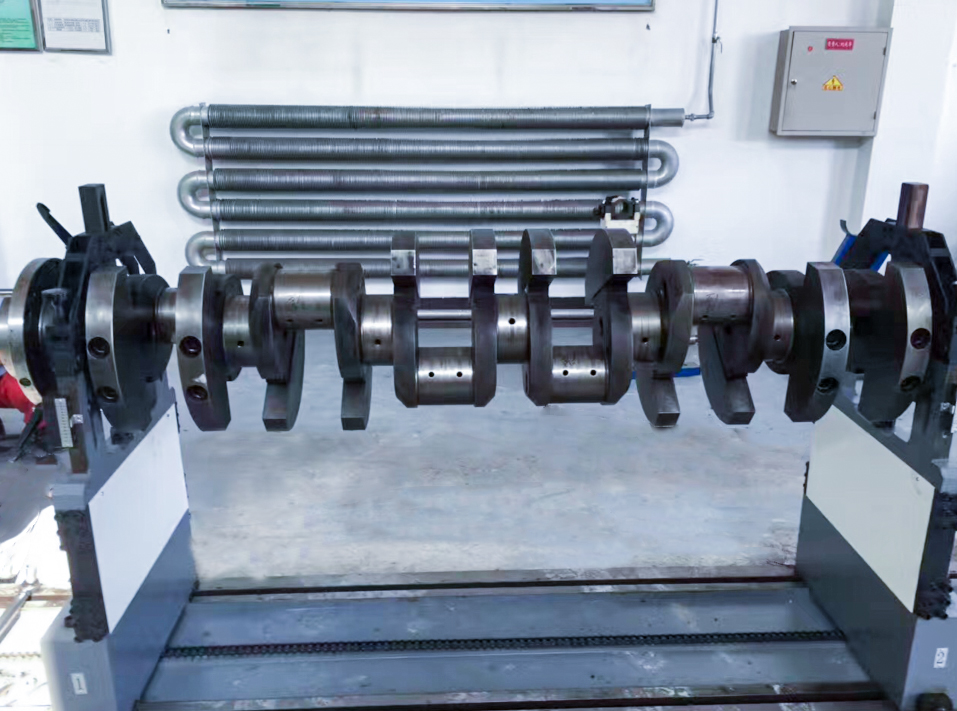

Due to the needs of industrial production development, Chinese manufacturers of dynamic balancing experimental machines began to gradually research and upgrade dynamic balancing machines early on. They developed and produced fully automatic crankshaft balancing machines and made crankshaft balancing machine test prototypes, taking the first step in the research of dynamic balancing automation technology in China.

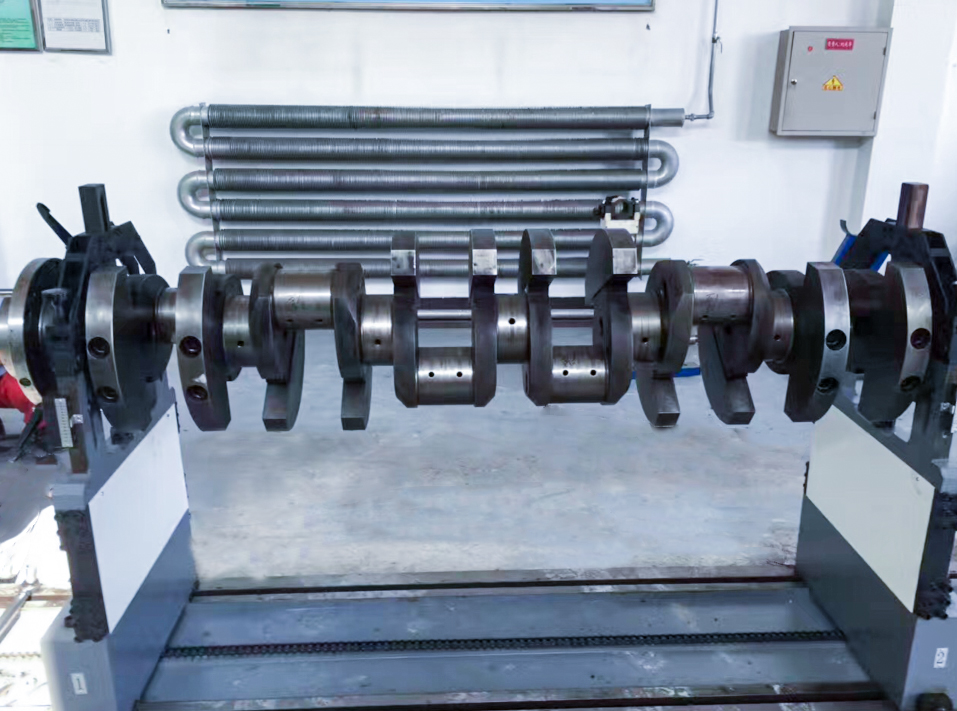

The energy-saving transformation of the frequency converter for the dynamic balancing machine is very important. The dedicated frequency converter for the dynamic balancing machine has comprehensive detection and protection functions such as overvoltage, undervoltage, overload, instant power outage restart, acceleration, deceleration, and stall prevention during dynamic rotation. The generally balanced rotor is placed on a dynamic balancing machine support supported by static pressure bearings, and a reflector is embedded below the support. Then, when the rotor is balanced, the light beam emitted by the light source is reflected by this mirror and projected onto the polar origin of the unbalance indicator.

If there is an imbalance in the rotor, the rotor support will tilt under the heavy torque of the imbalance, and the reflecting mirror under the support will also tilt and deflect the reflected light beam, causing the light spot on the polar coordinate indicator to leave the origin. Based on the coordinate position of the light spot deflection, the magnitude and position of the unbalance can be obtained.

The energy-saving transformation of the frequency converter for the dynamic balancing machine is very important. The dedicated frequency converter for the dynamic balancing machine has comprehensive detection and protection functions such as overvoltage, undervoltage, overload, instant power outage restart, acceleration, deceleration, and stall prevention during dynamic rotation. The generally balanced rotor is placed on a dynamic balancing machine support supported by static pressure bearings, and a reflector is embedded below the support. Then, when the rotor is balanced, the light beam emitted by the light source is reflected by this mirror and projected onto the polar origin of the unbalance indicator.

If there is an imbalance in the rotor, the rotor support will tilt under the heavy torque of the imbalance, and the reflecting mirror under the support will also tilt and deflect the reflected light beam, causing the light spot on the polar coordinate indicator to leave the origin. Based on the coordinate position of the light spot deflection, the magnitude and position of the unbalance can be obtained.

183 browse