Key points to note when using a dynamic balancing machine with displacement sensors

With the continuous upgrading of dynamic balancing machine technology, users who purchase dynamic balancing machines are increasingly requesting displacement sensors to be used on them. On the one hand, this type of sensor can improve the efficiency of dynamic balancing detection, and on the other hand, it can also save some costs for enterprises. Of course, the procurement cost of models with such sensors is slightly higher than that of ordinary models, but due to the improved detection efficiency, it can also save the company's overall labor costs.

The displacement sensor dynamic balancing machine is the main equipment for achieving automatic detection and control. The sensor can convert the detected information into signals or other forms of information output based on the characteristics of the information collected by the equipment. The working principle of the vibration signal converted by the sensor can be represented by three processes. The first process is to receive the vibration signal, the second process is to convert the vibration signal into a signal, and the third process is to convert the signal into a voltage signal, which can be used for subsequent balancing machine processing. Sensors still play a very important role in the rotor dynamic balancing machine testing system. In industrial production, we use a wide variety of balancing machine sensors, commonly including infrared sensors, displacement sensors, photoelectric sensors, etc. A speed sensor is a sensor that converts the rotational speed of a rotating object into power output. It can accurately measure the instantaneous speed of various motors used in automatic control systems and automation instruments.

Although displacement sensors can bring many benefits to mechanical manufacturing enterprises, there are also some things to pay attention to when using such sensors in dynamic balancing machines.

Firstly, the workpiece to be tested must have a special mark, which is not manually added after the product is formed, but reserved during the forming process, so that each product has this mark as soon as it is formed.

Secondly, not all workpieces can use this type of sensor. If you want to use it, it is best to first confirm with the dynamic balancing machine manufacturer whether your workpiece is suitable for using this model.

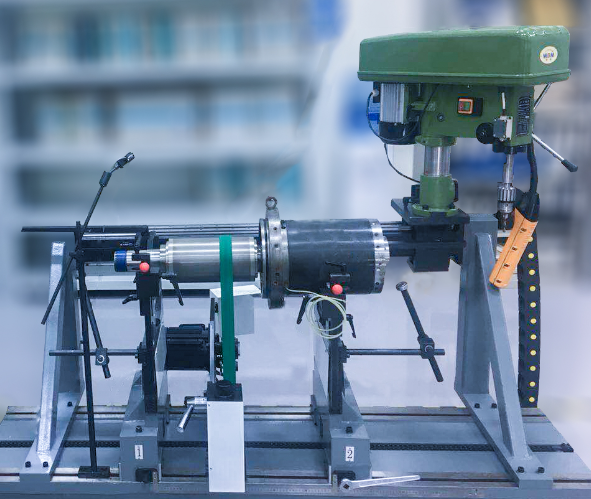

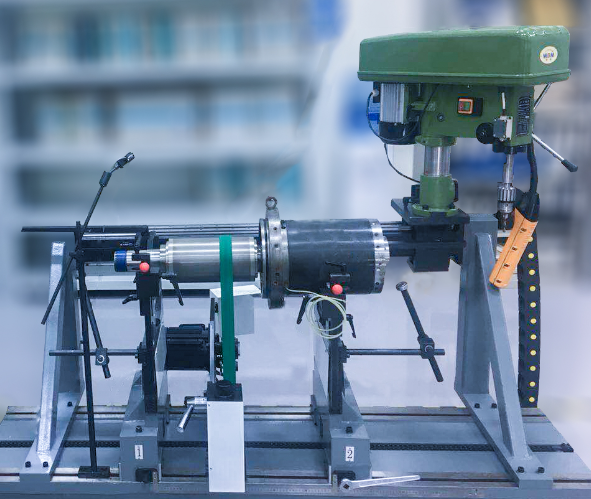

Displacement sensor balancing machine

Displacement sensors (commonly used eddy current sensors), commonly used inductive displacement sensors, capacitive displacement sensors, photoelectric displacement sensors, ultrasonic displacement sensors, and Hall displacement sensors. The working principle of a displacement sensor is to convert the physical displacement generated by the object being measured into corresponding electrical signals. Displacement sensors are mainly used for intelligent control of analog quantities in automated equipment production lines. The advantage is that the signal-to-noise ratio of the measurement signal is high, the measurement frequency range is wide, the vibration position can be directly measured, and it is easy to calibrate; The disadvantage is that it is inconvenient to install and requires the use of an external DC power supply.

The displacement sensor specifically reflects the size of the gap, the velocity sensor reflects the size of the energy, and the acceleration sensor reflects the size of the impact force. Due to the fact that vibration energy can accurately reflect the strength of vibration, the current vibration standards tend to use vibration intensity (velocity effective value) as the basis for judging the vibration state of equipment.

A speed sensor can convert the speed of object vibration into power output. It is a non-contact measuring device that can be manufactured through mechanical, electrical, magnetic, optical, and hybrid methods. The commonly used speed sensors are divided into magneto electric induction type, photoelectric effect type, Hall effect type, etc. The advantage is that it is easy to install. No need for external power supply, better performance in the intermediate frequency range of measurement, more suitable for medium speed rotors; Its disadvantage is that its performance will decrease after a period of use, and there will be a certain phase difference in low-frequency prediction.

An accelerometer is an electronic device that can measure acceleration. In physics, when an object is subjected to a force, it produces acceleration such as gravity. The acceleration force can be a constant, such as g, which can be a variable. Design an acceleration sensor based on this principle. Commonly used sensors include magnetic acceleration sensors, piezoelectric acceleration sensors, and fiber optic acceleration sensors. In unbalanced measurement, piezoelectric accelerometers are more common, with good reliability, easy installation, and suitable for measuring high-frequency vibrations. The disadvantage is that it is difficult to measure low-frequency vibrations and the measurement requires an external DC power supply.

With the continuous upgrading of dynamic balancing machine technology, users who purchase dynamic balancing machines are increasingly requesting displacement sensors to be used on them. On the one hand, this type of sensor can improve the efficiency of dynamic balancing detection, and on the other hand, it can also save some costs for enterprises. Of course, the procurement cost of models with such sensors is slightly higher than that of ordinary models, but due to the improved detection efficiency, it can also save the company's overall labor costs.

The displacement sensor dynamic balancing machine is the main equipment for achieving automatic detection and control. The sensor can convert the detected information into signals or other forms of information output based on the characteristics of the information collected by the equipment. The working principle of the vibration signal converted by the sensor can be represented by three processes. The first process is to receive the vibration signal, the second process is to convert the vibration signal into a signal, and the third process is to convert the signal into a voltage signal, which can be used for subsequent balancing machine processing. Sensors still play a very important role in the rotor dynamic balancing machine testing system. In industrial production, we use a wide variety of balancing machine sensors, commonly including infrared sensors, displacement sensors, photoelectric sensors, etc. A speed sensor is a sensor that converts the rotational speed of a rotating object into power output. It can accurately measure the instantaneous speed of various motors used in automatic control systems and automation instruments.

Although displacement sensors can bring many benefits to mechanical manufacturing enterprises, there are also some things to pay attention to when using such sensors in dynamic balancing machines.

Firstly, the workpiece to be tested must have a special mark, which is not manually added after the product is formed, but reserved during the forming process, so that each product has this mark as soon as it is formed.

Secondly, not all workpieces can use this type of sensor. If you want to use it, it is best to first confirm with the dynamic balancing machine manufacturer whether your workpiece is suitable for using this model.

Displacement sensor balancing machine

Displacement sensors (commonly used eddy current sensors), commonly used inductive displacement sensors, capacitive displacement sensors, photoelectric displacement sensors, ultrasonic displacement sensors, and Hall displacement sensors. The working principle of a displacement sensor is to convert the physical displacement generated by the object being measured into corresponding electrical signals. Displacement sensors are mainly used for intelligent control of analog quantities in automated equipment production lines. The advantage is that the signal-to-noise ratio of the measurement signal is high, the measurement frequency range is wide, the vibration position can be directly measured, and it is easy to calibrate; The disadvantage is that it is inconvenient to install and requires the use of an external DC power supply.

The displacement sensor specifically reflects the size of the gap, the velocity sensor reflects the size of the energy, and the acceleration sensor reflects the size of the impact force. Due to the fact that vibration energy can accurately reflect the strength of vibration, the current vibration standards tend to use vibration intensity (velocity effective value) as the basis for judging the vibration state of equipment.

A speed sensor can convert the speed of object vibration into power output. It is a non-contact measuring device that can be manufactured through mechanical, electrical, magnetic, optical, and hybrid methods. The commonly used speed sensors are divided into magneto electric induction type, photoelectric effect type, Hall effect type, etc. The advantage is that it is easy to install. No need for external power supply, better performance in the intermediate frequency range of measurement, more suitable for medium speed rotors; Its disadvantage is that its performance will decrease after a period of use, and there will be a certain phase difference in low-frequency prediction.

An accelerometer is an electronic device that can measure acceleration. In physics, when an object is subjected to a force, it produces acceleration such as gravity. The acceleration force can be a constant, such as g, which can be a variable. Design an acceleration sensor based on this principle. Commonly used sensors include magnetic acceleration sensors, piezoelectric acceleration sensors, and fiber optic acceleration sensors. In unbalanced measurement, piezoelectric accelerometers are more common, with good reliability, easy installation, and suitable for measuring high-frequency vibrations. The disadvantage is that it is difficult to measure low-frequency vibrations and the measurement requires an external DC power supply.

98 browse