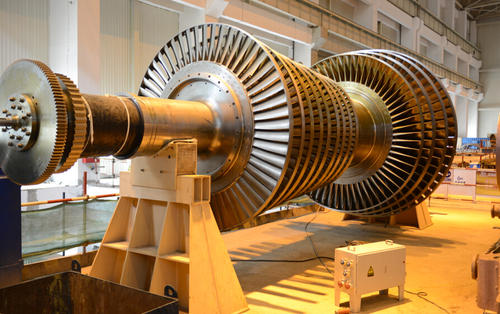

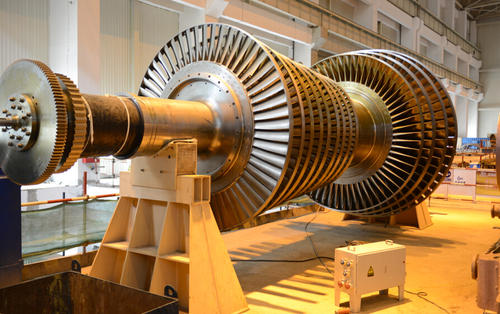

On site dynamic balancing of steam turbine generator units is the main method to solve vibration problems. On the one hand, 70% of vibration problems are caused by imbalance, and on the other hand, on-site dynamic balancing is relatively simple and feasible compared to other methods of dealing with vibration. On site dynamic balancing of steam turbine generator units belongs to the dynamic balancing of flexible rotor shaft systems, which is more labor-intensive and time-consuming than general on-site dynamic balancing. Therefore, high accuracy is required for on-site dynamic balancing, and to solve the unbalanced vibration problem of the turbine generator shaft system with the least number of times, rich experience in on-site dynamic balancing of the unit shaft system is necessary.

The safety and stability of the equipment and workpieces we use mainly depend on the presence of vibration, which is mainly caused by the imbalance of the shaft system. Today, we are going to learn about the high-speed dynamic balancing machine on site for steam turbine generator sets, which is the most effective solution for unit vibration.

We can operate based on the vibration theory of flexible rotors. Before dynamic balancing the rotor on site, a very important task is to determine whether the vibration mode of the unbalance on the rotor is first-order, second-order, or third-order. The rotor of a generator operating at the second-order critical speed will experience deformation of the second-order mode of vibration of the main span rotor due to the unbalance of the extended end, resulting in vibration characteristics similar to the third-order unbalance of the main span rotor. Practice has shown that reducing in-phase vibration can sometimes be difficult compared to other forms of vibration. We can use Bode plot for modal analysis of the rotor to determine whether the unbalance is in the same direction or in the opposite direction, whether it is within or outside the span. We can use weighting method to solve this problem.

Developing a weighted scheme for dynamic balancing is the most crucial step. On site dynamic balancing may have multiple weighting schemes based on the obtained raw data, and we must choose carefully. Firstly, we should ensure that the number of increased boot cycles is minimal. Secondly, in order to achieve the minimum residual vibration, we need to have a high degree of confidence in the weighting process and measurement results, and minimize the risk in order to implement the correct plan.

Operation steps for on-site dynamic balancing machine of steam turbine generator set:

1. Develop an implementable plan for the weighting of the dynamic balancing machine and determine the steps for the weighting operation.

2. Try to increase the weight and obtain weight data, this step is not necessary.

3. Measure the vibration data, analyze and record it.

4. Formally aggravated.

On site dynamic balancing has a history of several decades in the power industry, and it can be said that on-site dynamic balancing was initiated in the power industry. There are many people studying dynamic balancing in this industry, and many experts have conducted extensive theoretical research and accumulated rich experience in dynamic balancing time of shaft systems.

The safety and stability of the equipment and workpieces we use mainly depend on the presence of vibration, which is mainly caused by the imbalance of the shaft system. Today, we are going to learn about the high-speed dynamic balancing machine on site for steam turbine generator sets, which is the most effective solution for unit vibration.

We can operate based on the vibration theory of flexible rotors. Before dynamic balancing the rotor on site, a very important task is to determine whether the vibration mode of the unbalance on the rotor is first-order, second-order, or third-order. The rotor of a generator operating at the second-order critical speed will experience deformation of the second-order mode of vibration of the main span rotor due to the unbalance of the extended end, resulting in vibration characteristics similar to the third-order unbalance of the main span rotor. Practice has shown that reducing in-phase vibration can sometimes be difficult compared to other forms of vibration. We can use Bode plot for modal analysis of the rotor to determine whether the unbalance is in the same direction or in the opposite direction, whether it is within or outside the span. We can use weighting method to solve this problem.

Developing a weighted scheme for dynamic balancing is the most crucial step. On site dynamic balancing may have multiple weighting schemes based on the obtained raw data, and we must choose carefully. Firstly, we should ensure that the number of increased boot cycles is minimal. Secondly, in order to achieve the minimum residual vibration, we need to have a high degree of confidence in the weighting process and measurement results, and minimize the risk in order to implement the correct plan.

Operation steps for on-site dynamic balancing machine of steam turbine generator set:

1. Develop an implementable plan for the weighting of the dynamic balancing machine and determine the steps for the weighting operation.

2. Try to increase the weight and obtain weight data, this step is not necessary.

3. Measure the vibration data, analyze and record it.

4. Formally aggravated.

On site dynamic balancing has a history of several decades in the power industry, and it can be said that on-site dynamic balancing was initiated in the power industry. There are many people studying dynamic balancing in this industry, and many experts have conducted extensive theoretical research and accumulated rich experience in dynamic balancing time of shaft systems.

180 browse