How to choose the type of dynamic balancing machine for balance detection of brushless motors?

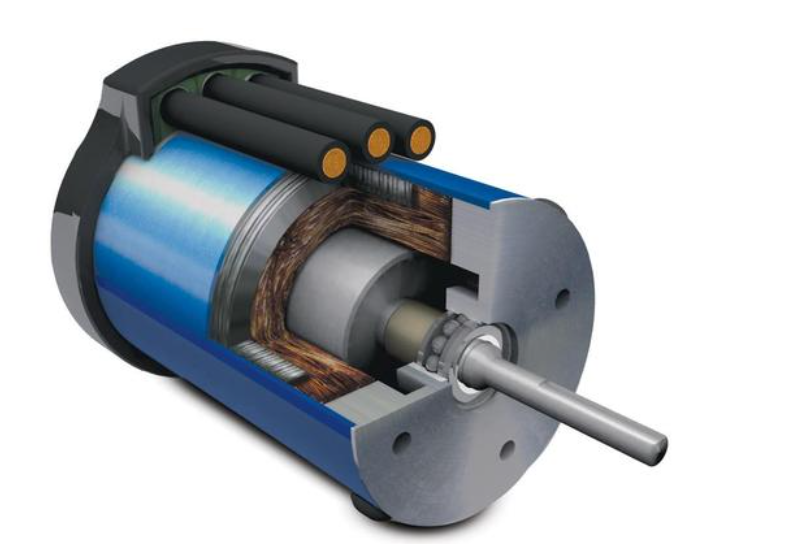

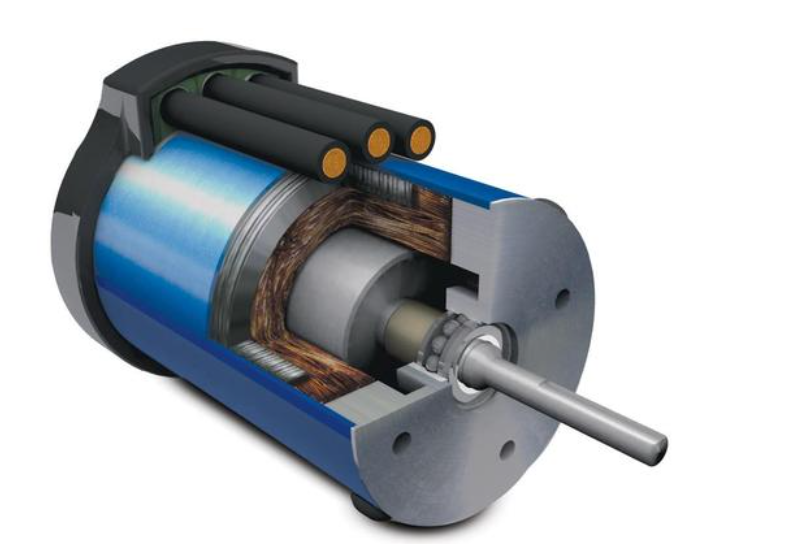

Brushless motors mainly consist of two parts: electric motors and drivers. Brushless motors belong to electromechanical integrated equipment. The development time of brushless motors in China is very short. With the rapid development of science and technology in our country, brushless motors have been applied in many fields, such as household appliances, toys, models, electric vehicles, and so on. Excessive use can also lead to various problems, among which one balance issue is the most critical. Let's learn together how to choose a dynamic balancing machine for brushless motors.

The centrifugal force generated by the uneven distribution of mass relative to the axis of any rotor during rotation around its axis can cause vibration, noise, and accelerated bearing wear on the bearings of the rotor, seriously affecting the performance and service life of the product. In order to control the vibration, noise, and service life of brushless motors, it is necessary to achieve a high level of rotor dynamic balancing accuracy. Choosing the brushless motor fully automatic balancing machine developed by Huake Zhichuang can effectively solve the dynamic balancing problem of the rotor and improve production efficiency.

When choosing a dynamic balancing machine, we should not just focus on the type of machine, nor blindly listen to others or online comments to choose the type of dynamic balancing machine. We should explore everything ourselves, and the answers we get are the best basis for judging the quality of the type.

The first thing to consider when choosing a brushless motor is whether to use a vertical dynamic balancing machine or a horizontal dynamic balancing machine. In fact, there is no definite answer or explanation for this. Because as long as any type of dynamic balancing machine can achieve high-precision and stable detection, then any type of dynamic balancing machine is acceptable. The purpose of testing is to see if the final result meets the user's requirements.

In addition, the accuracy and stability of the dynamic balancing machine detection are also the criteria for judgment. As long as a vertical or horizontal dynamic balancing machine is selected, whichever model can meet this requirement can be chosen. Some balancing machines have incorporated calibration devices as part of the balancing machine. Gravity balancing machines and centrifugal balancing machines are two typical types of balancing machines, and gravity balancing machines are generally referred to as static balancing machines.

Therefore, a balancing machine is an essential equipment for reducing vibration, improving performance, and enhancing quality. The balancing of a rotor usually involves two steps: measuring and correcting the unbalance. The balancing machine is mainly used for measuring the unbalance, while the correction of the unbalance is often accomplished by other auxiliary equipment such as drilling machines, milling machines, and spot welding machines, or by manual methods.

During the manufacturing process, rotating components such as motor rotors, machine tool spindles, internal combustion engine crankshafts and turbine rotors, gyroscope rotors, and clock balance wheels need to be balanced in order to operate smoothly and normally. The correction of the unbalance of the rotor based on the data measured by the balancing machine can improve the distribution of the mass of the rotor relative to the axis, reducing the vibration generated during rotor rotation or the vibration force acting on the bearings to within the allowable range.

Brushless motors mainly consist of two parts: electric motors and drivers. Brushless motors belong to electromechanical integrated equipment. The development time of brushless motors in China is very short. With the rapid development of science and technology in our country, brushless motors have been applied in many fields, such as household appliances, toys, models, electric vehicles, and so on. Excessive use can also lead to various problems, among which one balance issue is the most critical. Let's learn together how to choose a dynamic balancing machine for brushless motors.

The centrifugal force generated by the uneven distribution of mass relative to the axis of any rotor during rotation around its axis can cause vibration, noise, and accelerated bearing wear on the bearings of the rotor, seriously affecting the performance and service life of the product. In order to control the vibration, noise, and service life of brushless motors, it is necessary to achieve a high level of rotor dynamic balancing accuracy. Choosing the brushless motor fully automatic balancing machine developed by Huake Zhichuang can effectively solve the dynamic balancing problem of the rotor and improve production efficiency.

When choosing a dynamic balancing machine, we should not just focus on the type of machine, nor blindly listen to others or online comments to choose the type of dynamic balancing machine. We should explore everything ourselves, and the answers we get are the best basis for judging the quality of the type.

The first thing to consider when choosing a brushless motor is whether to use a vertical dynamic balancing machine or a horizontal dynamic balancing machine. In fact, there is no definite answer or explanation for this. Because as long as any type of dynamic balancing machine can achieve high-precision and stable detection, then any type of dynamic balancing machine is acceptable. The purpose of testing is to see if the final result meets the user's requirements.

In addition, the accuracy and stability of the dynamic balancing machine detection are also the criteria for judgment. As long as a vertical or horizontal dynamic balancing machine is selected, whichever model can meet this requirement can be chosen. Some balancing machines have incorporated calibration devices as part of the balancing machine. Gravity balancing machines and centrifugal balancing machines are two typical types of balancing machines, and gravity balancing machines are generally referred to as static balancing machines.

Therefore, a balancing machine is an essential equipment for reducing vibration, improving performance, and enhancing quality. The balancing of a rotor usually involves two steps: measuring and correcting the unbalance. The balancing machine is mainly used for measuring the unbalance, while the correction of the unbalance is often accomplished by other auxiliary equipment such as drilling machines, milling machines, and spot welding machines, or by manual methods.

During the manufacturing process, rotating components such as motor rotors, machine tool spindles, internal combustion engine crankshafts and turbine rotors, gyroscope rotors, and clock balance wheels need to be balanced in order to operate smoothly and normally. The correction of the unbalance of the rotor based on the data measured by the balancing machine can improve the distribution of the mass of the rotor relative to the axis, reducing the vibration generated during rotor rotation or the vibration force acting on the bearings to within the allowable range.

115 browse