Balancing machine master explains the knowledge points of dynamic balancing of range hood impeller

Range hoods, electric fans, exhaust fans, bathroom heaters, and even air conditioners are all fan type household appliances that rely on the high-speed rotation of impellers to drive the rapid flow of air in order to achieve their work goals.

We have always paid serious attention to the dynamic balance problem of the range hood impeller. When disassembling and measuring the structures of various range hoods, we pay special attention to the structural characteristics of the range hood impeller. When inspecting range hood manufacturers in Zhejiang, Jiangsu, Guangdong, etc., we intentionally learned about the degree of control each manufacturer has over the dynamic balance problem of the impeller. Therefore, we observed that some manufacturers are actually using the method of handling the dynamic balance problem of single-sided balance hood impellers to deal with the dynamic balance problem of double-sided balance hood impellers.

In fact, this issue is very easy to detect: if it is confirmed that the impeller belongs to a double-sided dynamic balancing machine, at least two balancing plates should be observed on the impeller; If the impeller belongs to the double-sided dynamic balancing category and only one balancing plate is observed, it can be considered that its dynamic balancing treatment of the impeller is inappropriate.

According to the ratio of the diameter of the fan impeller to the width of the impeller surface, also known as the "length to diameter ratio", the impeller can be divided into "single-sided dynamic balancing machine" impeller and "double-sided dynamic balancing machine" impeller.

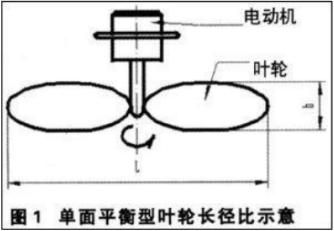

When the diameter of the impeller is 7-10 times larger than the width of the impeller (i.e. the projected thickness of the impeller side), or the aspect ratio is greater than l/10~1/7, it belongs to a single-sided dynamic balancing machine impeller. Electric fans, exhaust fans, etc. all belong to this type. In this case, if the impeller is found to have a dynamic imbalance problem, it is only necessary to install a correction mass with the same torque on any part of the diameter where the impeller center of mass is located. This can restore the center of mass of the impeller that deviates from the axis to the axis position, and put the impeller in a balanced state (see Figure 1).

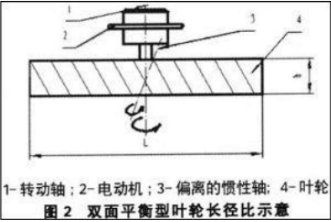

For impellers with aspect ratios less than 1/10~1/7, the above method is not applicable. impellers with aspect ratios less than 1/10~1/7 belong to "double-sided balancing machine" impellers. On the impeller of a double-sided balancing machine, when the impeller is in an unpowered state, if there are two equal masses arranged at symmetrical positions on both ends of the axis, the center of mass of the impeller does not show any deviation from the axis of rotation, and the impeller is actually in a state of "static balance"; But once the impeller enters a high-speed rotation state, the centrifugal forces generated by each of these two materials form a couple, and the inertia axis and rotation axis of the impeller no longer coincide, resulting in strong vibration of the impeller bearings; Or the two masses are also asymmetric, and the inertia axis and the rotation axis are inclined, so the center of mass of the impeller deviates from the axis, and the vibration of the impeller during rotation increases significantly. This is the most common phenomenon of dynamic imbalance in the impeller of a double-sided dynamic balancing machine. To eliminate the dynamic imbalance of the impeller, it is necessary to install calibration masses on at least two planes (see Figure 2).

In addition, the impeller of fan type household appliances is generally a "cantilever" rotor structure, which is only supported at one end where the impeller is connected to the motor spindle. The impeller is in a suspended state and can be regarded as a "cantilever beam" structure in structural mechanics. This cannot be ignored when analyzing the dynamic balance of oil fume engines (see Figure 2).

After knowing the classification method of the dynamic balance types of impellers, it is possible to make a judgment on the dynamic balance type to which the range hood impeller belongs. The range hood impeller belongs to the cantilever double-sided dynamic balance machine impeller. In the process of designing, manufacturing, installing, applying, and maintaining range hoods, it is crucial to have a clear understanding of the types and characteristics of the dynamic balance of the range hood impeller.

Based on the current data collected on the impellers of range hoods, it is believed that most of the impellers used in current range hood production should belong to the cantilever double-sided dynamic balancing machine impellers.

From the various range hood impellers disassembled and measured by technicians, it can be seen that the diameter of range hood impellers at present is usually around 200mm (190mm for slightly smaller diameters and 220mm for slightly larger diameters). According to the classification method of "single-sided balancing machine" impellers and "double-sided balancing machine" impellers, if the impeller diameter is 210mm, the width of the impeller (as centrifugal impellers are commonly used in range hoods, their width status is very obvious from the side) should be between 21-30mm; That is to say, when the width of the impeller of the range hood is not greater than 30mm, the impeller with a diameter of 210mm can be balanced with a single-sided balancing method to ensure that the range hood will not experience abnormal vibration due to the dynamic balance state of the impeller during high-speed operation.

Range hoods, electric fans, exhaust fans, bathroom heaters, and even air conditioners are all fan type household appliances that rely on the high-speed rotation of impellers to drive the rapid flow of air in order to achieve their work goals.

We have always paid serious attention to the dynamic balance problem of the range hood impeller. When disassembling and measuring the structures of various range hoods, we pay special attention to the structural characteristics of the range hood impeller. When inspecting range hood manufacturers in Zhejiang, Jiangsu, Guangdong, etc., we intentionally learned about the degree of control each manufacturer has over the dynamic balance problem of the impeller. Therefore, we observed that some manufacturers are actually using the method of handling the dynamic balance problem of single-sided balance hood impellers to deal with the dynamic balance problem of double-sided balance hood impellers.

In fact, this issue is very easy to detect: if it is confirmed that the impeller belongs to a double-sided dynamic balancing machine, at least two balancing plates should be observed on the impeller; If the impeller belongs to the double-sided dynamic balancing category and only one balancing plate is observed, it can be considered that its dynamic balancing treatment of the impeller is inappropriate.

According to the ratio of the diameter of the fan impeller to the width of the impeller surface, also known as the "length to diameter ratio", the impeller can be divided into "single-sided dynamic balancing machine" impeller and "double-sided dynamic balancing machine" impeller.

When the diameter of the impeller is 7-10 times larger than the width of the impeller (i.e. the projected thickness of the impeller side), or the aspect ratio is greater than l/10~1/7, it belongs to a single-sided dynamic balancing machine impeller. Electric fans, exhaust fans, etc. all belong to this type. In this case, if the impeller is found to have a dynamic imbalance problem, it is only necessary to install a correction mass with the same torque on any part of the diameter where the impeller center of mass is located. This can restore the center of mass of the impeller that deviates from the axis to the axis position, and put the impeller in a balanced state (see Figure 1).

For impellers with aspect ratios less than 1/10~1/7, the above method is not applicable. impellers with aspect ratios less than 1/10~1/7 belong to "double-sided balancing machine" impellers. On the impeller of a double-sided balancing machine, when the impeller is in an unpowered state, if there are two equal masses arranged at symmetrical positions on both ends of the axis, the center of mass of the impeller does not show any deviation from the axis of rotation, and the impeller is actually in a state of "static balance"; But once the impeller enters a high-speed rotation state, the centrifugal forces generated by each of these two materials form a couple, and the inertia axis and rotation axis of the impeller no longer coincide, resulting in strong vibration of the impeller bearings; Or the two masses are also asymmetric, and the inertia axis and the rotation axis are inclined, so the center of mass of the impeller deviates from the axis, and the vibration of the impeller during rotation increases significantly. This is the most common phenomenon of dynamic imbalance in the impeller of a double-sided dynamic balancing machine. To eliminate the dynamic imbalance of the impeller, it is necessary to install calibration masses on at least two planes (see Figure 2).

In addition, the impeller of fan type household appliances is generally a "cantilever" rotor structure, which is only supported at one end where the impeller is connected to the motor spindle. The impeller is in a suspended state and can be regarded as a "cantilever beam" structure in structural mechanics. This cannot be ignored when analyzing the dynamic balance of oil fume engines (see Figure 2).

After knowing the classification method of the dynamic balance types of impellers, it is possible to make a judgment on the dynamic balance type to which the range hood impeller belongs. The range hood impeller belongs to the cantilever double-sided dynamic balance machine impeller. In the process of designing, manufacturing, installing, applying, and maintaining range hoods, it is crucial to have a clear understanding of the types and characteristics of the dynamic balance of the range hood impeller.

Based on the current data collected on the impellers of range hoods, it is believed that most of the impellers used in current range hood production should belong to the cantilever double-sided dynamic balancing machine impellers.

From the various range hood impellers disassembled and measured by technicians, it can be seen that the diameter of range hood impellers at present is usually around 200mm (190mm for slightly smaller diameters and 220mm for slightly larger diameters). According to the classification method of "single-sided balancing machine" impellers and "double-sided balancing machine" impellers, if the impeller diameter is 210mm, the width of the impeller (as centrifugal impellers are commonly used in range hoods, their width status is very obvious from the side) should be between 21-30mm; That is to say, when the width of the impeller of the range hood is not greater than 30mm, the impeller with a diameter of 210mm can be balanced with a single-sided balancing method to ensure that the range hood will not experience abnormal vibration due to the dynamic balance state of the impeller during high-speed operation.

131 browse